1. Evaluate your current storage system

The first step in improving your warehouse storage is to assess your current system. Take a close look at your inventory and determine if you are utilizing the available space effectively. Are there any bottlenecks or areas of inefficiency? This evaluation will help you identify the areas that require improvement.

2. Implement a clear organization system

A well-organized warehouse is essential for smooth operations. Consider implementing an efficient organization system, such as the ABC method. Categorize your inventory based on its importance, with category A being the most frequently accessed items and category C being the least. By placing highly demanded items closer to the shipping area, you can reduce unnecessary travel time and increase efficiency.

3. Utilize vertical space with racking systems

One of the most effective ways to maximize your warehouse storage is by utilizing vertical space. Install racking systems that allow you to stack items vertically. This will help you take advantage of the available height in your warehouse. Choose the right type of racking system based on your inventory and space requirements.

4. Consider mezzanine floors

If you have a high ceiling in your warehouse and require additional storage space, consider installing mezzanine floors. Mezzanine floors are an excellent option for warehouses with limited floor space. They create an extra level where you can store goods, freeing up the ground floor for other operations. Mezzanine floors are customizable and can be designed to fit your specific needs.

5. Implement an efficient picking and packing process

An inefficient picking and packing process can lead to wasted time and decreased productivity. Optimize your process by organizing your inventory logically and utilizing batch picking. Batch picking involves grouping orders together and picking them simultaneously, reducing travel time and improving efficiency. Invest in technology that can streamline your picking process, such as barcode scanners or automated picking systems.

6. Utilize cross-docking

Cross-docking is a method that eliminates the need for long-term storage. It involves unloading incoming shipments and immediately loading them onto outgoing trucks, reducing handling and storage time. This method is particularly beneficial for perishable goods or time-sensitive shipments. Consider implementing cross-docking in your warehouse to speed up the supply chain.

7. Implement proper labeling and signage

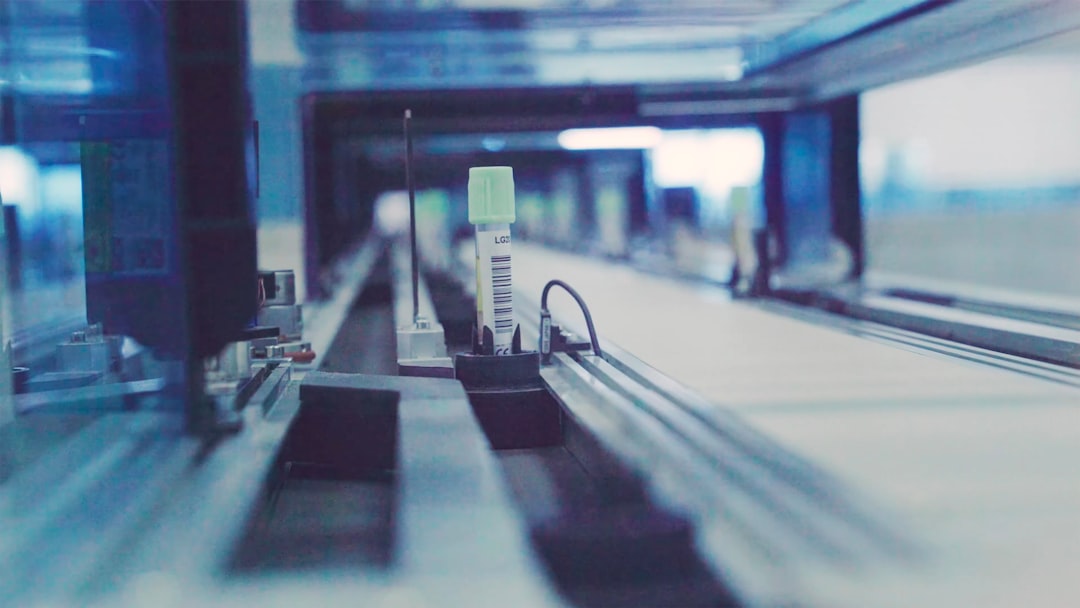

Clear labeling and signage are crucial for efficient warehouse operations. Properly label each item and designate specific areas for different types of inventory. This will ensure that your employees can easily locate and retrieve items. Additionally, consider implementing a barcode or RFID system to track inventory and monitor stock levels accurately.

8. Regularly review and optimize your storage system

Warehouse storage needs are constantly evolving. Regularly review and assess your storage system to identify areas that can be optimized further. Analyze your inventory flow, demand patterns, and operational requirements. This will help you make informed decisions about reorganizing or expanding your storage space.

In conclusion, efficient warehouse storage is essential for maximizing productivity and streamlining operations. By evaluating your current system, implementing a clear organization system, utilizing vertical space, and optimizing processes, you can make the most of your warehouse storage in Sacramento. Don’t let a lack of space hinder your operations. With these strategies, you’ll be well on your way to a more efficient and organized warehouse.